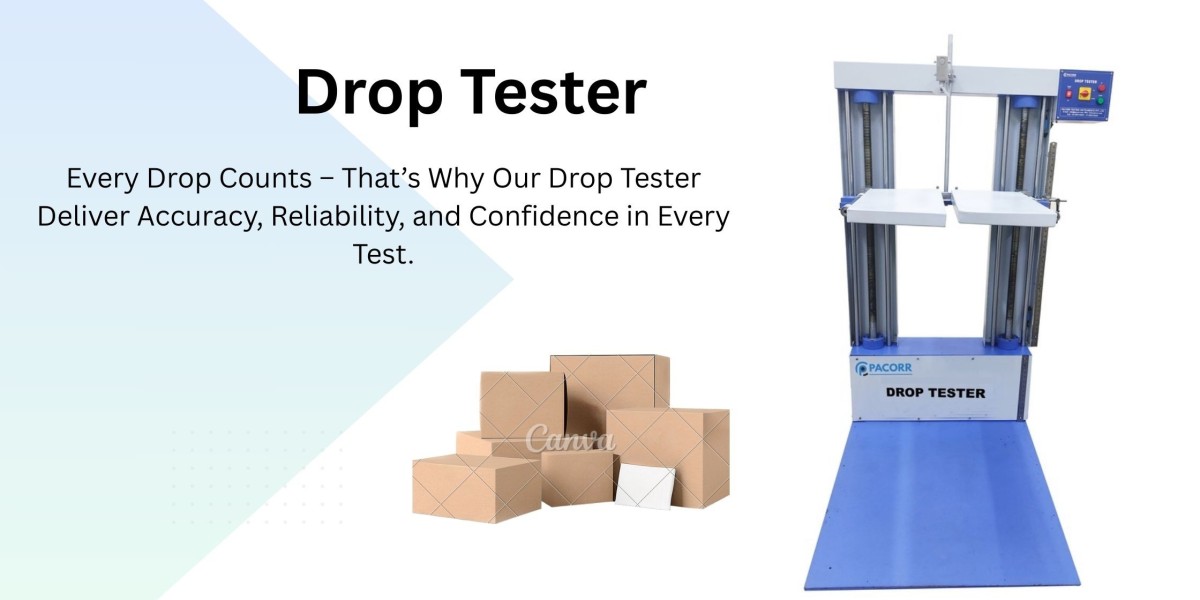

At Pacorr.com, we provide reliable, high-performance Drop Testers that help manufacturers across industries simulate real-life drop scenarios. Our testing equipment is engineered to reveal weaknesses, validate packaging, and improve product safety—ensuring what leaves your factory arrives intact at its final destination.

What Is a Drop Tester?

A Drop Tester is a testing machine designed to replicate the impact a product or package might experience when dropped from a specific height. This simulation allows manufacturers to assess the shock resistance of both the product and its packaging.

Drop testing evaluates how items handle vertical impact when landing on different surfaces such as flat panels, corners, or edges. With this data, businesses can make informed decisions about packaging design, material selection, and product improvements.

Why Drop Testing Matters

✅ Reduces Product Damage

Whether you’re shipping electronics, cosmetics, or industrial components, your product must survive the trip. Drop testing reveals vulnerabilities that could lead to breakage, allowing for proactive design changes.

✅ Decreases Return Rates

Customers expect to receive products in perfect condition. Damaged goods lead to costly returns, negative reviews, and lost trust. By using drop testers, businesses can drastically reduce damage-related returns.

✅ Enhances Packaging Efficiency

Drop testing doesn’t just make packaging stronger—it makes it smarter. Data from testing helps packaging designers create solutions that balance protection with material usage, reducing excess packaging and costs.

✅ Ensures Compliance with Standards

Many industries are required to meet global testing standards like ISTA, ISO, and ASTM. Pacorr’s Drop Testers make it simple to carry out standardized tests to help your products meet international shipping and safety guidelines.

Features of Pacorr’s Drop Testers

At Pacorr, we build drop testing machines with quality, accuracy, and long-term reliability in mind. Our drop testers are suitable for a wide range of product types and packaging configurations.

? Adjustable Drop Heights

Choose from a range of drop heights to simulate different handling scenarios—from short drops during packing to falls from warehouse shelving.

? Multiple Drop Orientations

Test products on their flat surfaces, edges, and corners to identify all potential impact points and packaging weaknesses.

? Stable Clamping Mechanism

Our dual-arm clamp holds the product securely in place before releasing it in a precise vertical drop, ensuring consistent results every time.

? Rugged, Industrial-Grade Build

Manufactured with high-quality, corrosion-resistant materials, Pacorr drop testers are made to withstand continuous use in demanding environments.

? User-Friendly Operation

Simple controls and clear indicators make it easy to perform accurate tests with minimal training, helping you integrate drop testing seamlessly into your QA process.

Industries That Benefit from Drop Testing

? Packaging

Drop testing is essential for packaging developers and manufacturers who need to prove that their designs provide sufficient protection during shipping.

? Electronics

From smartphones to small appliances, electronic products require packaging that cushions both internal components and outer shells. Drop testing verifies shock protection.

? Cosmetics & Health Products

Bottles, tubes, and jars—especially those made of glass—must withstand movement and impact. Drop testing ensures secure packaging and product integrity.

?️ Retail & E-Commerce

In the online shopping era, products pass through multiple hands before reaching customers. Drop testing helps maintain the customer experience by reducing the risk of damaged deliveries.

? Tools & Hardware

Even heavy-duty items need protection. Drop testing ensures tools don’t cause or suffer damage in transit.

Types of Drop Tests Conducted

Pacorr Drop Testers allow you to perform a variety of impact simulations:

Flat Drop: Product is dropped on its base, top, or side.

Edge Drop: Tests durability when impact occurs along an edge.

Corner Drop: Evaluates the strength of corners—often the weakest part of packaging.

By running multiple test types, you can gain a complete picture of how your product and packaging will perform under various conditions.

Best Practices for Drop Testing

To make the most of drop testing, consider the following tips:

Test Real Products in Final Packaging: Use the actual product and its complete packaging to get the most accurate results.

Run Multiple Trials: Perform several drops to account for variations and confirm consistency.

Document Test Data: Keep detailed records of height, orientation, and outcome to analyze trends and inform packaging decisions.

Test Early in Development: Perform drop testing during the product and packaging design phase to prevent costly changes later.

Simulate Real-World Scenarios: Match your test conditions to how products are actually handled in storage and shipping.

Why Choose Pacorr.com?

At Pacorr, we provide more than just machinery—we deliver dependable testing solutions. Our Drop Tester Price are trusted across industries for their durability, precision, and ability to support a wide range of testing needs.

Why Pacorr Stands Out:

? Custom Configurations: Tailored testing machines to suit your specific product dimensions and weight.

? Accurate & Repeatable Results: Precision-built mechanisms deliver consistent performance test after test.

? Dedicated Support: Our experts provide training, setup assistance, and ongoing technical support.

? Global Quality Standards: We help you align with international testing requirements for product safety and shipping readiness.

Final Thoughts

In a world where product quality can make or break a brand, drop testing plays a crucial role in customer satisfaction and long-term success. Pacorr’s Drop Testers help you protect your products, reduce damage, and deliver excellence—no matter how far your items need to travel.

Visit Pacorr.com to explore our full range of Drop Testers and elevate your quality control process. Test smarter. Ship safer. Build better.